Farming History of Ken Enns

Ken’s father, Peter H. Enns, was born on Mar. 9, 1906 in Schoenfeld, Russia, a very prosperous community that was totally destroyed in the early days of the Russian Revolution. The family fled for their lives and came to Canada in the early 1920’s. They had little, but had a faith in God, and came to a country willing to let them live in peace, while giving them the opportunity for a new beginning.

Ken, the middle child of five, was born on Oct. 7, 1944 to Peter and Susie (nee Koop) Enns. Ken spent his early years following his father around the farm. He sat on the tractor floor, at his father’s feet as crops were being planted and cultivated. Ken recalls observing his father dealing with the various issues of growing crops, repairing and installing equipment and eventually building a small starter greenhouse. Those early days were difficult for the family and Ken remembers his father placing a $20.00 bill on the dinner table one evening, saying this was all that was left from the summer’s work. As a result, father spent the winter months working in a local factory, a common experience among farmers in those days.

In his early childhood Ken watched as the crops were being planted and the first small greenhouses were being built. He observed the processes of planting and growing the various field and greenhouse vegetables. In the greenhouse, the soil had to be first dug up and then sterilized with steam. It was hard work and somewhat dangerous working with hot steam. Ken recalls hours and hours being spent watering plants by hand, all the time thinking of what he would rather be doing. In those days there were no computers to regulate the opening and closing of vents, control temperatures and irrigation. Everything was done manually, 24 hours a day, summer and winter. During those years Ken was unknowingly being prepared for what was yet to come.

Ken loved school and learning. He would have continued on that path had not his father, Peter, suffered a heart attack and met an untimely death in 1962. He died shortly before Ken was to deliver the valedictory address for his grade 12 UMEI graduating class.

His mother wanted him to accept the scholarship he eventually won from the University of Windsor, to continue his education. Ken felt he had no alternative but to turn the scholarship down and try and keep the farm functioning, since his older sisters were already married with their own families, and his twin younger brothers were too young to take over. Ken accepted this as God’s plan for his life, and decided to stay on the farm and help a devastated mother hold the farm together with all of its debts and challenges. He tried to keep his studies up for one year longer, taking correspondence courses and attending half days at Leamington District Secondary School, but this eventually proved impossible.

Mother kept ownership of the farm, although Ken was mainly responsible for its operation for the next 5 years. His younger brothers eventually took on some of the responsibility. Dennis, in time, received an engineering degree, while Dave attended university for three years and then joined Ken on the farm. It had already started to grow, with Ken having bought a similar farm across the street. As the farms continued to grow, a corporation was formed.

At the very young age of 21, and only three years after his father’s passing, Ken married, on Dec.30, 1965, his already long time sweetheart, 19 year old Rita Konrad. After a brief honeymoon they came home to the realities of life, which meant literally living in the greenhouse. Their children were raised in the greenhouse, and graduated from playpen to working beside their parents. Eventually, when the time came, the work would be divided between all members of the family. The beginning of married life started as a very labour intensive and hard occupation, mainly because the greenhouse operation remained relatively small, as most greenhouses were at that time.

The expansion of the greenhouse business came about slowly at first, governed by how much the Enns family could afford to invest in it. The growth of the greenhouse operation rose exponentially however as technology changed. The transformation was revolutionary. Everything that in the beginning was done by hand, such as watering, temperature management and sterilizing, was now done by the computer, which rapidly changed the small family farm into a large, scientifically exact, and minutely managed food production facility.

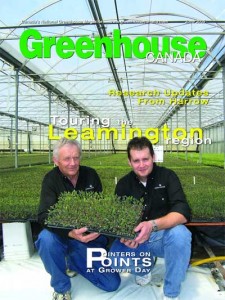

In later years Ken’s son Steven came along, eventually taking Dave’s place. Steve’s brother Paul became a lawyer, and their sister Lisa, a pastor. Steve stayed home to work together with his father, assuming some of the risks of farming and thus started the next generation in the family business.

The greenhouse area now covers almost 40 acres and employs about 100 people year round. Much of the physical labour has been replaced with technological advances. The cucumbers and tomatoes are planted in glorified eaves-troughs containing fibreglass and are about 1 meter above the ground. All work associated with the plants is now done at waist level from moving scissor-lift, travelling cars. Back-breaking stoop labour is a thing of the past. Since the plants are being grown in fibreglass their roots do not go out into the soil to find the essential nutrients. Everything must be artificially supplied to them. Scientists have removed one element at a time from the plant food mixture to see how it affects plant growth. The result is a plant food formula intended to produce maximum plant health and as a result maximum plant production. As a consequence some 20 elements, including copper, zinc, boron, molybdenum, calcium and other elements must be carefully monitored, along with the normal macro-nutrients. Ultra violet light is used to keep the growing media sterile and free from disease.

Ken says he has no regrets about his life’s direction. His son Steve has now assumed most of the responsibility of operating the farm, while Ken is always near by. Ken says he feels richly blessed because his parents fled to a country where he has been able to live out his faith, while working at what he enjoyed and raising a family that can carry on where he leaves off.